12 Steps to Cam Replacement and Break-in

Camshaft Assembly Lube & Break in Lube

Part of my 1963 Ford Falcon engine build is researching how to build and break-in the engine… the right way.

To get great advice, I asked the experts at Edelbrock. They’ve been building engines and hot rod parts forever… not to mention they’ve been very cool helping me with my engine build and with MyRideisMe.com. Hope these tips are helpful!

Tech with Edelbrock: Camshaft Break-in for Hydraulic Flat Tappet Camshafts

Upgrading your hydraulic, flat tappet cam is a very popular performance upgrade. In many cases, cam changes happen independently of a complete engine rebuild. With or without engine rebuild, when changing cams, proper steps must be taken to ensure a hassle-free installation, break-in period, and of course, good cam and lifter life.

The following are the basic steps for camshaft break-in. Read and follow the included instructions with every Edelbrock cam and lifter kit. We’re skipping the assembly and disassembly steps because there’s too many variations to cover it all.

1) Always use new lifters with a new camshaft. Do not use existing lifters with a new camshaft. Cam lobe wear is almost non-existent unless mismatched parts are used or installation of the cam and lifters is done improperly. Don’t take a shortcut by re-using lifters. They’re fairly cheap and a must for a new cam.

You can use the same assembly lube on all bearing surfaces, like the main caps shown here.

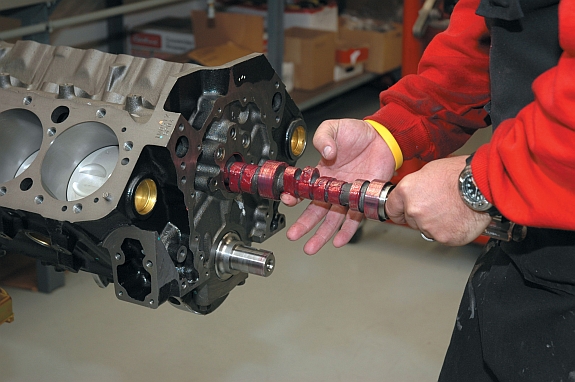

2) Cover the cam lobes and bearing surfaces, and the lifter faces completely with a high quality engine assembly/cam lube. The days of using Vaseline are long gone.

3) Carefully install the camshaft, take caution as lobe edges are sharp. You don’t want to nick or scratch the cam bearings.

4) After applying assembly lube to the lifter faces, install lifters into lifter bores. Make sure lifters turn and rotate easily inside the bore. What does “easily” mean? Good question… You can check your own engine’s specs, but a rule of thumb is not more than 0.0015 clearance for a performance motor.

5) Install new cam sprockets and timing chain. Make sure timing marks are lined up correctly. Follow factory specs and instructions. Most cam damage is caused by the timing gear coming loose due to improper torque on bolt. Bolts holding gear to camshaft should be torqued carefully and a locking compound applied to threads of bolts.

6) Lube timing chain and gears with engine break-in oil.

7) Make all necessary valve adjustments. (The details of this would be the topic of another how to…)

8) Install distributor and adjust engine timing (TDC). Follow factory specs.

9) Use a proper grade motor oil for break-in, such as Edelbrock SAE 30 break-in oil.

10) Run engine above 2,000 rpm and vary up to 3,000 rpm for 1/2 hour for proper break-in.

Cam break-in side note…

Sometimes when starting a new motor, things don’t go perfectly to plan… timing’s not right, carb isn’t adjusted right, you name it… worst of all, you’re running the motor standing still, so there’s almost no air flow. In that case, there’s a risk for overheating. So what if you need to shut down the motor before you’re finished? Nothing! Fix it, let it cool, whatever you need. Just make sure you’ve done the full 30 minutes before you hit the streets. (Why not share your experience in a comment below?)

11) Change motor oil and filter. After the engine has been run and the cam is broken in, use an appropriate motor oil to protect the valvetrain components such as Edelbrock Performance 10w40 and Zinc additive. Engine oils have changed with the change in valvetrain tech such as roller cam/lifter combos. When using a flat tappet cam, make sure to get an oil with Zinc. Also, on the oil filter, get an everyday, ordinary (ok, cheap) filter. You’ll be throwing it away after only 30 minutes! Replace it with a high quality filter.

A little more about Zinc in your Oil:

Traditional oil blends included additives such as zinc and phosphorus added through a component known as ZDDP (zinc dialkyl-dithios-phosphate) to aid in lubricity of flat tappet lifters and camshaft lobes, especially at break-in. The EPA has done its part in identifying these ingredients as contributors to tailpipe emissions. For that reason, the standard for passenger car oils, known as ILSAC GF-4, changed and no longer contains ZDDP. Even without the lowered emissions, the oil most likely would have still changed. Roller cams and lifters have much lower friction, as compared to flat tappet, so they simply don’t need the ZDDP.

12) Double check all components and make sure everything is leak-free.

Proceed to local cruise and enjoy!

Got another question for Edelbrock? Let’s hear it! I’ll do my best to get an answer…