Auto Meter Data Acquisition Review – Time for 200MPH+

Auto Meter STACK for Bonneville Salt Flats Racing

From the analog data of “Old School” and to accuracy, speed and ease of digital data logging. That’s the simple goal here. From there, the Volk Brothers Racing 1929 Model A roadster is looking to use the data at the race track to modify or update the engine setup to ultimately go fast and break a record. Then, the reality of salt flats racing steps in…

Photo courtesy of SCTA website

Backing up a step, Auto Meter Gauges, Volk Brothers Racing and MyRideisMe.com teamed up for Speed Week 2010 and World of Speed for some high speed runs down the Bonneville Salt Flats. Our salt infested friends, the Volk family, run a Ford roadster with a fuel injected big block Chevy engine. They compete in the B/GR (373ci-449ci engine/Racing Gas, Roadster) class at Bonneville during Bonneville Speed Week and the Utah Salt Flats Racing Associations World of Speed.

The Volk family salt flat racing pedigree includes (what seems like) 200 mph club membership for everyone of driving age in the Volk family. To get in the two-club, you have to set a record and run over 200 mph. Starting with Dad, Larry Volk, he’s the outgoing president of the two-club, and sons Dallas and Pat, and daughter Alison, are also 200 mph club members running this roadster. With the success of the Volks family racing, it was a no-brainer for Auto Meter to team up.

The Volks and their roadster (aka “the brick that could”) have held various records, including the B/GR record in the past. The class record was and still is (for this year anyway) 232.346 MPH set by Wilson & Waters in 2003. With a fresh engine, fresh black paint and the new Auto Meter STACK Pro Comp Data Logger, hopes were high for another record and a two-club “Red Hat” for drivers Brady Nish (yes, of the veteran land speed racing Nish family) and Chauncey Filler.

Review of Auto Meter Stack Pro Comp Data Logger

Below, Dallas Volk tells recaps the Auto Meter STACK gauge install, general review, setup and advantages over their previous tuning methods.

Below, Dallas Volk tells recaps the Auto Meter STACK gauge install, general review, setup and advantages over their previous tuning methods.

Let me start with a little background: The Volk Brothers Racing team’s been running since the 60’s and we’ve set many records with a top speed of 250+ MPH.

Our tuning for the last 40 years has been “old school” using analog gauges for temperatures and oil and fuel pressure . After every run we’d read plugs to check air/fuel condition (rich or lean) then decide if we needed to retard or advance timing. We’d rely on the drivers memory of analog gauge readings to give us oil pressure and water temp data throughout the run and his/her feelings on whether the clutch is slipping all while trying to keep a 200 mph rolling brick on a straight line for 5 miles. Needless to say, the data’s not as accurate as an engine tuner would desire… This is an obvious advantage for a data acquisition system.

Keep this on the down low: As a driver, I used to lie about shift point rpm’s because one blower motor had a cam with a 200 HP nitrous shot-like burst at 5200 rpm. The car wanted to swap ends at speed and I didn’t!. The motor owner wanted me shifting at 7000 rpm’s which dropped me to 5000 rpm’s after the shift. To avoid the 200 mph hula I would shift at 7400 to keep after-shift R’s at 5400. The motor owner would throw a rod if he knew this. Shhhhhh…

This photo shows what the Auto Meter gauges used before the data logger setup. These gauges saw 20+ years of usage in the rough and salty Bonneville environment.

After much research, and some guidance from Auto Meter, we decided to go with the Auto Meter STACK Pro Comp Data Logger. The high-tech data logging system should be great for tuning, but a sad day for hiding shift rpm’s from engine owners!

To get started, a new dash was fabricated from aluminum with the hole cut out for the STACK unit. (Thanks to our friends from Structural Steel and Plate in North Salt Lake City, Utah) I can already see the benefit of the single gauge because its one object to look at instead of four. Imagine trying to look at four separate gauges while driving over 200 mph.

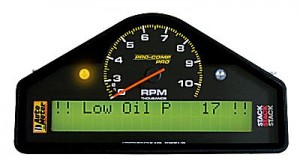

Why this Data Logger? First reason: The Auto Meter data logger interface. Starting with the classic Auto Meter tach, below is a simple and easy to read LED display where the driver can monitor up to four different inputs clearly. The data logger will also display alarms for anything you’re measuring such as low oil pressure. Again, an alarm or “idiot light” for critical info at speed was a huge benefit for the team.

STACK unit is installed, now time to wire it up with the various sensors.

Second reason: We reviewed many different data logging systems and knew that Auto Meter was a strong manufacturer of gauges (our previous set-up had all Auto Meter gauges) but Auto Meter wasn’t well known in the data logging world. I had heard from some people that Auto Meter didn’t put out a very good product for data logging. What these people didn’t know, and I actually found out from a “techie” of a competitor, is that Auto Meter teamed with a company called STACK. STACK made the Auto Meter data logging systems as reliable and user friendly as the gauges Auto Meter’s known for.

The backside of the dash showing the wiring for all the sensors.

The Install

Once we received our data logger and sensors we started the install. The sensors we decided to go with for now (we will be adding more) were two pressure sensors, one for oil and one for fuel at the nozzles, one water temp sensor, drive line RPM, and two O2 sensors, one for each collector. The install went great! With the new 3/8″ aluminum dash, we slipped the data logger in and started stringing wires and connecting sensors.

Oil Pressure sensor plumbed and wired up.

Fuel Pressure sensor hooked up at the intake manifold.

The install was very easy and the only thing to be cautious of is documenting which sensors go to which ports on the race data logger.

This is a screenshot showing how each sensor is programmed into the STACK.

Programming the sensors to the data logger was equally easy. Auto Meter and STACK did a great job on their GUI in the setup program. Just grab the picture of the sensor type you want on the screen and drag it to the input you want. I couldn’t be happier with how easy the install was.

The STACK unit and the associated wiring and converter next to the potent Big Block Chevy.

Using the Race Car Data Acquisition

OK… here’s where we ran into a little trouble. The user instructions for operation of the STACK are pretty weak . The instructions explain how to setup the programming but oddly enough I couldn’t find how to start the actual data logging! At first then, we used the laptop connected to the data logger on the starting line to start and stop data logging. It was by accident while our driver was resetting the low oil pressure alarm that he held the reset button for three seconds and the display read “logging run”. We already mentioned this to Auto Meter and they’re checking into it.

Larry Volk wearing his 2-Club Red Hat while installing sensors and bundling the wiring along side son Pat.

Other than the simple problem of actually recording the race data… the system performed flawlessly! After the first run at 218 mph, we were amazed at how much the data helped. We could see air/fuel mixture, oil pressure, water temp, fuel pressure, and clutch slip recorded side by side throughout the entire run. Our driver also noted how easy it was to read the display in the darkness of the cockpit.

All the data were were getting was cool, but we all thought about how much we’d been missing using old school tuning and troubleshooting. I don’t know how we made it without some of the other functions too. We programmed an alarm to go off at a certain temperature so the driver knew when to turn on the water pump without having to monitor the temp gauge, and another alarm for low oil pressure, a potential engine saver! Having these alarm features and the improved visibility of the tach allows the driver to focus on driving. That’s great for both safety and performance.

Conclusion

I highly recommend the Auto Meter Pro Comp STACK. It was very easy install, and overall, very easy to run. The data mining and configuring is easy and has the ability to stack one run on top of the other for comparison which is really cool to see the improvements (or not!) your tuning work did. For the future, the data logger can handle many sensors so we plan on adding O2 sensors on each exhaust pipe rather than just at the collector so we can tune each cylinder. We’lll put another fuel pressure sensor at the pump too so we can compare between pressure at the pump and the nozzles.

I wish we would have gone this route years ago.

Thanks Dallas! Sounds like the Auto Meter STACK gauge and data logging setup is perfect for land speed racing. Thanks to the Volk Bros Racing Team for sharing this info with us at MyRideisMe. See below for more photos of the install.

i was considering the Racepack unit for my car, but this one sounds more appealing. With big names like Autometer and Stack, i think this is the better choice

Hi!

I was looking for stories, feeders and so on for an article about sensors and their use in dealing with safety, energy efficiency and so on in the motoring world. I came across this blog and thought it so good that I’d like to use a mention of it in my article.

Essentially the IEC is responsible world over for the International Standards of anything electric, electronic or that carries, manufactures or distributes electricity. So, you can see where the sensor part fits in.

Would you mind my mentioning you and using a couple of your photos?

Sounds great! I’ll Let Auto Meter know about it too. Would you like to contact the author of this story?

This is a very nice article and pics!! I saw the youtube video and fell in love with the sound of that big block chevy. I have never heard one sound that crisp and awesome!! Someday I will make it to the Salt. Thanks for sharing your video and article. V/R Terry