Agent Orange – Stuffed and Huffed 1968 Camaro

Homebuilt and Driven Hard 1968 Camaro

Words and Pictures by Joe Casvin

(click on any picture to see it full size)

Most people just use their garages to store the stuff that just kind of builds up throughout life. Treasures like newspapers from 1976, a ten-year-old brand new exercise bike, or even a dingy and probably nasty smelling old cooler. You know, shit house door of a tuna boat smell? Jeff Chipman’s garage, however, had a far better hand to be dealt.

Jeff used his garage to transform a bare 1968 Camaro shell into something that is both frightening and beautiful. Not an easy feat for your average Joe in your average two-car garage, and when you compound that with the fact that this is Jeff’s first ever attempt at building a car from the ground up… Well, you end up with something that is truly special and unique. “My first rig was a 1950 Chevy pickup I got when I was 15 years old. I started doing stuff to it after I got it. I’ve been messing around with cars and bikes all my life, just customizing them here and there“, claimed Chipman.

Jeff started his journey into functional automotive art by purchasing a 1968 Camaro body and sub frame with the intentions of doing a stock restoration. Soon after, he started to do his homework on the parts that he would need, Jeff made a discovery that would change the direction of the restoration. Jeff recalled, “Once I started to look for the parts I would need for the car. I noticed that, in some cases, stronger better parts were usually not that much more than the stock pieces I was looking at. Sometimes, even less. So for me the choice was pretty easy.” Stock too ludicrous, isn’t it great? Definitely a mindset I think we all can live with.

When it came time to start building the chassis for his creation, Jeff contacted Chris Alston’s Chassisworks to supply the pieces to make back halving the car a little easier. After getting the rear frame rails and four link in place, Jeff hung one of Alston’s FAB9 rear ends to finish up fabrication in the rear. The burly rear end was then stuffed with 4.56 gears, an Eaton posi, and Dutchman 35 spline axels. Jeff then fabricated some frame rail connectors to give his car a solid foundation that could resist the tantrums of the angry and powerful barker that would soon live, mostly, under the hood. With the front end and the rear suspension tied together, Jeff installed QA1 coil overs all around to give his car a decent ride and some extra adjustability. Jeff also scored a set of Centerline Convo Pros that give his car a little nastier attitude and reduces un- sprung weight.

After getting the frame and suspension done, Jeff could then attack the rest of the car. He got busy and tinned in part of the floor, the trunk, and the wheel tubs. With the tin in like Flynn, Jeff cut and bent all of the moly tubing for his roll cage, then welded it all in place.

Following the interior metal work, Jeff started to have some ideas about getting the outside of the car to match up with what the gears in his head were telling him. To make himself and the gears happy, Jeff got cracking on the exterior of the body. He ditched the rear fuel filler opening, marker lights, emblems, and exterior trim pieces to get the car looking a bit smoother. While he was giving his car a shave, he also cut and lengthened the rear wheel arches to give the massive 33/21.50 Mickey Thompson Sportsman’s a beefier more aggressive look. Then he went to town on the bodywork, getting his beauty ready for the show. Up to this point Jeff had done all of the work himself, saving a heaping pile of nickels in the process.

To get his baby to the start line a little sooner, Jeff finally got some of his buddies to come in and tackle some of the project with him. Luckily one of Jeff’s buddies, Steve Arnold, had the time, space, and talent to spray out the glassy smooth finish on Jeff’s ride. After Jeff picked a color that is about as subtle as a full-scale alien invasion, Steve laid down the super nova bright House of Kolors Tangelo Pearl to really set the car off. Jeff saved even more cash by trading his fabrication talents on one of Steve’s projects in return for Steve squirting the paint on Agent Orange. As with most pictures of cool paint jobs, it is nothing like being right next to the car. The finish is highly polished and as smooth as glass. If you were standing next to the car, the paint looks as if you could reach right in and feel the warm glow of the color on your skin.

While Jeff and Steve were prepping the car for paint, Jeff had Ron Thompson, of Bowtie Performance in Turner, Oregon, getting down on a 482 cubic inch big block that would soon provide smiles and fear for the still developing Agent Orange. To match the looks of the car, Jeff knew the engine would pretty much have to be a wild screaming banshee. So Jeff had Ron pack the big block with all the good stuff. The block got a forged steel crank that swings forged 7/16 rods with Wiseco pistons to help try to contain all the madness. To give the big block some vocal authority, Ron went with a Comp Cams hydraulic roller unit for the bump stick. The valve lift is .612, with a duration of 255 on the intake, and .605-inch lift, and a duration of 266 out the backside.

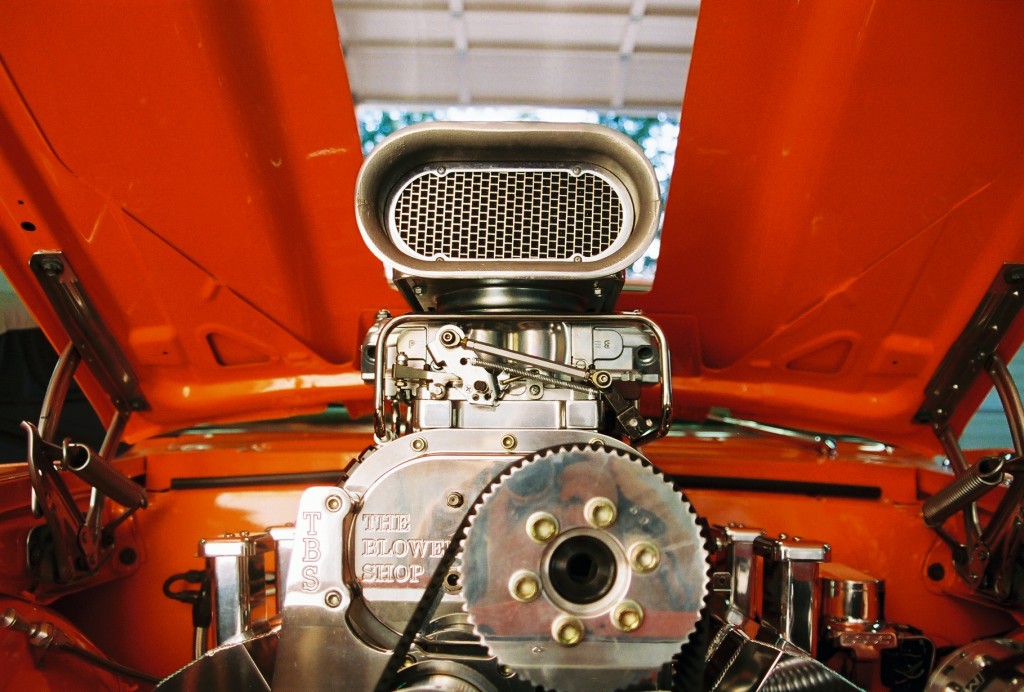

To top off the thumper, a set of GM rectangular port cylinder heads got the full port and polish treatment then bolted down to the stout block. When it came down to getting the induction in order. Jeff knew he wanted a blower that would not only make a statement, but also be capable of sucking in enough air to vacuum ten large homes at once. With this in mind, Jeff picked up a fully polished 8-71 billet piece form The Blower Shop. A pair of hungry Demon 850 cfm double pumper carbs were then used to match up to the hurricane winds that would soon be squeezing into the big block. How much power did all of these parts make together? “This combo with a little more boost, a larger cam, and bigger carburetors made about 1300 hp. So with these smaller carbs and cam, I’m guessing right at about 1000 hp”, speculated Chipman. All of the banshee’s anger is routed through a built Turbo 400 that is loaded with a reverse manual valve body, billet hubs, and Kevlar clutches. There is also a TCI 3,500 rpm stall converter to help get the car out of the hole with haste.

I can tell you from personal experience; this thing pulls harder than a team of steroid injected Clydesdales. Going down the road at about 45 mph, Jeff barely touched the throttle, and vaporized about a hundred dollars off the steam roller M/T’s. This car is like Charlize Theron with Mike Tyson’s viscous right cross. It’s brutal. It is refreshing to see a car built to this level that sees regular street duty. Not only does he drive it habitually, but he beats on it like it owes him money. I’ve seen, it’s really cool!

Trust me, to see this car driven hard is awesome. But it’s not as cool as the fact that Jeff built almost the entire car himself in his garage. How much money do you think he saved by doing the work himself? Enough to buy a small eastern European country? Probably not, but definitely enough to spice up the juicy bits with a shiny new billet huffer.

I just hope you get at least enough inspiration to go out into your garage and use it for something other than storage or to park your kiddy shuttle. Just like Rome, this car wasn’t built in a day. “It took me three years to get the car to this point. I was busy, so I just spent two or three hours here and there on the car. Basically whenever I had spare time I would be out in my garage working. I could have gotten it done a lot faster, but I wanted to learn how to do this for myself”, explained Chipman. The knowledge Jeff gained during his build is key. Now Jeff’s building a 67 Nova that will be just as radical as Agent Orange. It’s the circle of life in mechanical form. Sure, having a couple of those nickels to rub together helps. But if you have enough drive and passion, money won’t ever stop you. So get out there and build something fast!