Salt Flats Speed Shop: Traditional Hot Rod Builder

Salt Flats Speed Shop in Orem, Utah is run by Chris Davenport, a metal fabrication and finishing craftsman and hot rod builder who is dedicated to building 1930’s traditional hot rods. Chris has been in business officially for about 2 years now and is attracting more and more customers as the word gets out about his affordable, high quality craftsmanship.

Salt Flats Speed Shop in Orem, Utah is run by Chris Davenport, a metal fabrication and finishing craftsman and hot rod builder who is dedicated to building 1930’s traditional hot rods. Chris has been in business officially for about 2 years now and is attracting more and more customers as the word gets out about his affordable, high quality craftsmanship.

“Need a Chop, a roof insert, fender, or a quarter panel? Well you’ve come to the right place. We’ll fix all your cars issues, and have it looking as good in “bare metal” as it did when it was made.”

Chris (in the white shirt) showing us around his shop in Orem. This is a customers 3 window coupe with suicide doors. We dropped in on Chris Thanksgiving week. He willingly took an hour or more to give us the full shop tour. He explained all his tools, showed us all his projects and talked shop. I could tell Chris is passionate about hot rods!

I had emailed Chris letting him know that a friend and I wanted to drop in and check out his shop. My friend, Gary, has a 1928 Model A Pickup of his own and found Salt Flats Speed Shop on the Jalopy Journal forums, which is where I originally spotted Chris’ handy work as well.

I checked out Chris’ website saltflatsspeedshop.com and was amazed at the craftsmanship and skill involved in the metal repair and custom fabrication I saw in his projects page.

Chris is building his own Salt Flats Speed Shop 1932 Model A Tudor Sedan to show off what he can do. Please take a few minutes to see his detailed H.A.M.B. ’32 Tudor build thread. My favorite project at the shop was Chris’ ’32 Tudor. If you’re subscribed to the build thread like me, you’ll know that he’s planning on taking the car to Speedweek 2010 and actually racing on the Salt. Chris has period correct frame and body modifications underway, including a 4.5″ to 5.5″ chop top (amount of chop not totally decided), a ’32 pickup grille, schroeder steering box, ’40 Ford steelies with dirtrack Firestones and a hot 8 BA Flathead V8 with a race cam, Edelbrock heads, an Offy 2 carb intake setup and 5 speed behind it (hey, might as well take advantage of modern tech’ for better mpg and driveability).

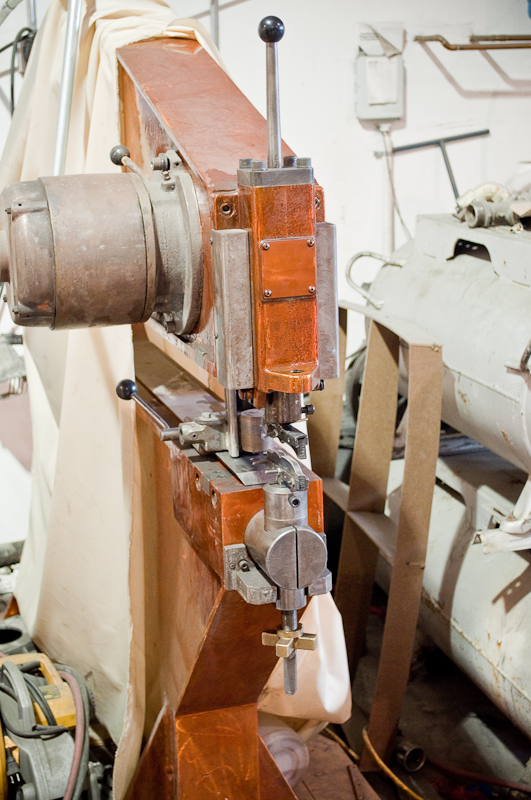

To build an old school hot rod, you gotta have old school metal working tools. Let’s take a peek at Salt Flats Speed Shop’s tools of the trade shall we…

Here are just some of the metal working tools used to perform any number of repairs or fabrication. Close up of an English Wheel (used to put a crown in a door skin or roof insert), standard millin/drilling station and a Lenox Nibbler (Louvers, shrinking and shearing and beads).

I liked this shelf hanging on the wall full of rolling dies in many shapes and sizes. Chris said he can replicate any body line from the 20’s, 30’s and 40’s with his equipment.

Chris is doing some restoration and repair (R&R ha ha) on a friends Porsche project. Cool rotissiere stand! Chris made that too! Obviously!

Here’s a look from one end of the shop to the other to get a look at some of the project cars. You’ve got the 32 Tudor, a 3 window coupe, the Porsche, the aluminum 1940 Willy’s (that’s right, aluminum) and another 3 window coupe. So cool! Lots of bare metal in this shop!

I believe most of these are spoken for, but that is a nice collection of Model A Pickup cabs ready to be turned into hot rods.

This last picture is cool. A closeup of the die set on that Lenox Nibbler that will do wonders with a flat sheet of steel.

So there you have a quick glance at Salt Flats Speed Shop. Check out their website and 32 Tudor build thread. I hope to bring more of the ’32 Tudor to MyRideisMe.com in 2010.

Go and visit theSalt Flats Speed Shop Website

Hechtspeed

Hechtspeed,

What a Fantasic Article!

Just the right amount of Written Material Punctuated by some Fabulous Photo’s.

Chris sure has an awesome set up.

I’m a novice car enthusisast and found this article to be very informative and inspirational.

Keep up the great work.

Napster

Thanks Napster! Glad you liked it. Chris at Salt Flats Speed Shop has tons of potential. He’s still early in his career as a hot rod builder and has already done some amazing work! Just tryin’ to spread the word!

That is a great inside look of the hot rod building process!

there is only one word to describe his work ………………….fantastic. i’ve been working in the industry for 30 yrs and built several rides. a friend purchased one of chris’s projects and the work is killer. always looking forward to his next pictures that he post on the projects he is doing.

watch his work and awwwwwwww over it

2streetrods

tom

HI

i just bought a 1930 ford model a pickup they welded sedan back on of the pickup cab so it’s wrong i’m looking for a pickup cab. hopefully you might help me or maybe you know someone else I live in columbus nebraska.

THANK YOU

CHUCK NIEDBALSKI

moc.liamgnull@deinsahc

I am a fabricator with many years of it. I really want to form sheet metal. I understand shrink and stretch, but I feel I can learn to be a 1920’s metal former. To me that is true craftsmanship. I would like to offer myself for free! I will fab custom A arms, sand and prep for paint. I am really good with body fillers, and aluminum fabrications. I just want to learn to make a complex body panel without filler. I will pay for the material I mess up as long as we keep it mild steel. I feel you guys have nothing to lose, and I have everything to gain. If I can learn to make a right and left ’32 ford front fenders, than I can make anything!