When I had the 289 CID motor in this car, engine oil temperature was not a problem and at times it ran cool. The installation of the 383 (stroked 351W) changed all of that. Any extended driving or repeated hard acceleration would push the engine oil temperature up to 240º, and sometimes to the end of the gauge at 250º. Water temperature appeared to be stable, and no more than a couple of degrees warmer than with the smaller motor, so it appeared I had to remedy an oil temperature problem. Some of the options for mounting the cooler were: 1) In front of, or behind the radiator which created problems directing the oil supply hoses to and from the cooler. The design of the car has the engine radiator sealed by body/hood panels to ensure forward motion air pressure is forced through the radiator with minimal losses around it. Attaching the oil cooler to the radiator would require cut or modified body panels, extended lengths of hose, and the general dissatisfaction of having a cooler attached to the radiator through the fins using the typical plastic fasteners. The...

Falcon Build Update #4 Tailgate Drama

Ford Falcon Wagon Tailgate I should have called this "The Good, The Bad and the Ugly" as I update everyone on the MyRideisMe.com 1963 Falcon Wagon build. It no doubt I drastically underestimated the work needed to get ready for paint! Also, my plan for the Falcon changed from a quick paint job to, "I might as well do it right" which of course is the right way to go. I've made some good progress on the body work even though Arizona's held 100-plus degrees making it damn hot in the garage. It'll be another 20 days before it cools down, so waiting's not an option. Damn! I'm writing about the weather! Want the good, the bad or the ugly? OK, bad first. Remember the blog when I showed off my skills filling the back-up lights in the tailgate. Please disregard everything I said! I screwed up that tailgate beyond reasonable repair, at least for me. Luckily, I have Mr. Freeze, (my buddy Rob) backing me up with another tailgate on hand (and rust free!). The original tailgate was repaired (another big pile of manure the...

Bodywork 101 – Patience to make it flat

Bodywork 101 - Straighten a Body Panel like Pro You can’t expect to learn bodywork in 1 afternoon, no matter how good the teacher is, but one thing’s for certain: You’ll never learn unless you get in there and try it. This blog and the ones that will follow will show some basic bodywork techniques anyone can do (especially if I can do it!). Since I’m starting from nothing, I hope the pictures and videos will help you get started too. Just starting, that’s where I am with my 1963 Falcon Wagon build. The body’s really not that bad, but after 45 years on the road, a Sherman tank needs panel work before glossy paint. As I mentioned in the "Holman & Moody Boss 429 - (you should read this)" I headed over to Squeeg’s Kustom to get started learning. I hooked up with Matt Vesay and interrupted his work on a stretched Dearborn Deuce body to get started on the upper splash apron (just above the front bumper) from a custom getting painted. The panel was fiberglass, but that didn’t really matter for what I needed...

Book Review: Build Book – From Concept to Reality

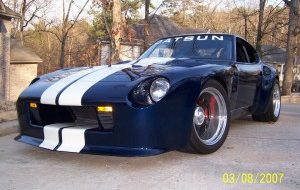

You're walking around a show and when you see a car cruise in that makes you stop in your tracks. You're stunned and instantly curious. You're hear it and feel it as it drives by. Time for a closer look. Cars that make you feel that way have alot to see, but it's all skin deep. What'd he do for the rear axle setup? Are those custom engine mounts? Unless the builder took great pics and brought them, it's tough to fully appreciate what it took to bring that car to the show. That's where Build Book comes in. BuildBookUSA.com has published 5 books covering 5 cars built by some of the top builders in country. I met Scott and BJ Killeen (long time auto journalists) at the Grand National Roadster Show and they were kind enough to let me preview the complete series of books. You gotta check these out! The first book, and my favorite, is about Joe Rogan's "Sick Fish" 70 Barracuda. Built by the legendary Troy Trepanier & Rad Rides by Troy, this book oozes coolness page by page. What do you want to know...

Welding to Win with Joe Gibbs Racing

Welding to Win with Joe Gibbs Racing® Courtesy of Lincoln Electric Hidden along a tree-lined parkway of unmarked office buildings in suburban Charlotte, North Carolina, lies a brand new steel-and-glass white structure that could be home to any number of corporations in any industry. But through the main door it becomes clear that this is something more than an insurance agency or software firm. It's home to Joe Gibbs Racing®, bejeweled in trophies, racing jackets and display cases literally filled with artifacts from the nation's fastest growing sport. Past the receptionist, across the main lobby, an observation deck overlooks one of the most advanced auto shops in the world. Through a panel of high windows is a conspicuous absence of grease stained floors and stray tools. Instead, the vast open space of more than 150,000 square feet shines in pristine white and better resembles an operating room than a fabrication shop. It's a virtual racecar laboratory, where engineers work side-by-side with master fabricators to create the fastest machines possible within the guidelines established by their sport. Those team fabricators, in turn, rely on the welding experts at Lincoln Electric®...

How To Weld Aluminum with a Compact MIG Welder

How To Successfully Weld Aluminum with a Compact MIG Welder from Lincoln Electric By Jim Harris®, Product Manager, The Lincoln Electric Company and Frank Armao, Group Leader, Non Ferrous Applications, The Lincoln Electric Company When it comes to welding aluminum items around the home or garage, there are a few misconceptions we hope to clear up: 1) That you need to invest in a $4,000 welding machine and be highly skilled to have success; 2) With no practice you can make excellent welds the first time the wire feed welder is taken out of the box; and 3) You need an expensive spool gun suited for aluminum. The truth is that with practice, the right equipment and proper set-up, a compact MIG welder will be able to tackle occasional aluminum welding jobs. Using your MIG welder, you will be able to work on a variety of items around your home and yard, such as grills, railings, backyard furniture, boat docks and even decorative elements. Compact MIG welders, such as the SP, Weld-Pak or Pro models from Lincoln Electric, are available at distributors and retail outlets. A Word About Aluminum...