5 Things to Know About Performance Pushrods

Trend Pushrods – New Ways to Combat Pushrod Troubles

Seeking and finding stories about great engine builders and the high performance parts they use, every once in a while, you find yourself asking. “What makes xyz so special?” In this case, I got to talking about high performance pushrods and didn’t know much about them. Luckily, Trend Performance makes pushrods for everybody from the weekend warrior to the best of NHRA and NASCAR. So I asked a few questions…

An interview with Bob Fox, founder of Trend Performance

By Sam Logan with photos by Moore Good Ink

Today the Michigan firm Trend Performance is the largest manufacturer and supplier of pushrods in racing and the performance aftermarket. But in 1988 when Bob Fox founded his pushrod company, after working the phones as a tech rep at Diamond Racing, things were different. During his time at the piston company, he noticed that the performance of competition pushrods was little better than adequate—their lengths varied and their ends failed—both ends! Manufacturers would reduce the material thickness of the cup ends in order to form them, and as a result they would crack. Further, their lengths were so inconsistent that each pushrod had to be inspected and graded accordingly. It was this encounter that caused Fox to contemplate life as a pushrod maker.

Today the Michigan firm Trend Performance is the largest manufacturer and supplier of pushrods in racing and the performance aftermarket. But in 1988 when Bob Fox founded his pushrod company, after working the phones as a tech rep at Diamond Racing, things were different. During his time at the piston company, he noticed that the performance of competition pushrods was little better than adequate—their lengths varied and their ends failed—both ends! Manufacturers would reduce the material thickness of the cup ends in order to form them, and as a result they would crack. Further, their lengths were so inconsistent that each pushrod had to be inspected and graded accordingly. It was this encounter that caused Fox to contemplate life as a pushrod maker.

1. What are the biggest challenges that face today’s competition pushrod maker?

- Excessive surface roughness contacting the pushrod

- Pushrod balls bound in tight cups, especially V-cups

- “Point loading” of pushrod end

- “Point loading” of pushrod end

“Racers seeking to exploit every tiny advantage tend to select lighter and lighter weight oils, many of which are impaired or even deficient in lubricity at high loads and high revs. Also, installing pushrods positioned between lifters and rockers with contact surfaces rougher than 1Ra expose the pushrod ends to severe abrasion. For example, a rocker arm adjuster ball with a rough, hard contact surface can act like a file. Plainly, it’s prudent for the engine builder to inquire about the surface finishes of the parts that operate in conjunction with the pushrods.”

What’s 1Ra? Ra refers to the surface roughness average (Ra) also known as the arithmetic average (AA). It’s the average of a surface’s peaks and valleys expressed in micro inches. 1Ra is about as smooth as you can get.

“Another factor that leads to premature failure occurs when pushrod balls are bound in tight cups. It’s imperative they have sufficient operating clearance. A further problem arises when you set the ball end of a pushrod in a V-cup. The V-cup presents a very narrow contact seat which significantly increases the loading on the pushrod ball end. If its seat is heat treated to a very hard condition, it will eventually pound its V-shape into the pushrod ball. Much more desirable is to set the pushrod ball end in a radius cup and reduce the point loadings.

Recently, I was reminded by Jon Kaase, the race engine builder, of the severe environment in which the pushrod operates. ‘Assume,’ he said, ‘you have an open spring pressure of 1,400lb and a rocker ratio of 1.9:1, therefore, the loading on the pushrod equates to around 2,660lbs. This is then transmitted through the tiny area of the pushrod ball. If the surface area of a V-cup is 100th of a sq. in., the loading could be somewhere around 300,000 psi!’ In addition to these loadings, increased rocker ratios and engine revs further increase surface speeds on the ball ends.”

2. How long do pushrods last in racing engines?

- In NASCAR – one or two races

- In NHRA – until they show signs or wear or discoloration

- In Short track racing – several seasons

“In Sprint Cup, the top teams might use them only once or twice and then switch them to their Busch Series engines. Other Cup teams will run them much longer. In NHRA

“In Sprint Cup, the top teams might use them only once or twice and then switch them to their Busch Series engines. Other Cup teams will run them much longer. In NHRA

Pro Stock, most of the teams will run them until they show signs of wear. The same is true in Top Fuel and Funny Car, except those pushrods might show signs of discoloration on their ends instead of wear. If they begin to turn blue from excessive heat, it’s time to replace them. In short track oval racing, engine builders will use the same pushrods for several seasons—often six to eight thousand laps—providing they are not bent and show no signs of wear.”

3. What percentage of your pushrod business is racing?

“Probably ninety percent of our production is devoted to racing. But Trend also produces piston pins and tool steel flat tappets for racing, particularly NASCAR. About one half of our valve train production serves professional race teams; the other half is dedicated to the weekend racers and to the high-performance street users.”

4. Do you make single-piece or three-piece pushrods?

“Trend doesn’t make three piece pushrods, but we do manufacture two-piece. These allow the engine builders to cut the pushrods to length and install the tips as required. Our tips are pressed into the pushrod using a hydraulic press and an installation tool. But a few years ago, when we introduced a Quickship program, we discovered most engine builders preferred one-piece pushrods. These were finished to size and length— they required no more work—and they’re shipped within 24 hours.”

5. What materials are used to manufacture pushrods?

“The biggest proportion is made from chrome molybdenum, a type of alloy steel known as 4130. This material possesses an excellent strength-to-weight ratio and is considerably stronger and harder than standard 1020 steel. Sprint Cup engines use it as do much of Pro Stock and Pro Mod. In contrast, Top Fuel and Funny Car teams use H13 tool steel in solid bar form. The 4130 pushrods are produced from thick-wall tubing. Their hollow center passage is pressurized by oil destined to lubricate the rocker adjuster.”

‘Strength-to-weight ratio’ is a commonly measured attribute of steels known as ‘specific strength”. Specific strength is the strength or yield stress divided by the material density.

Source:

Trend Performance

23444 Schoenherr

Warren, MI 48089

(586) 447-0400

www.TrendPerform.com

Pushrod ball ends are checked for size by a coordinate measuring machine. Trend holds this tolerance to plus-or-minus 0.001in.

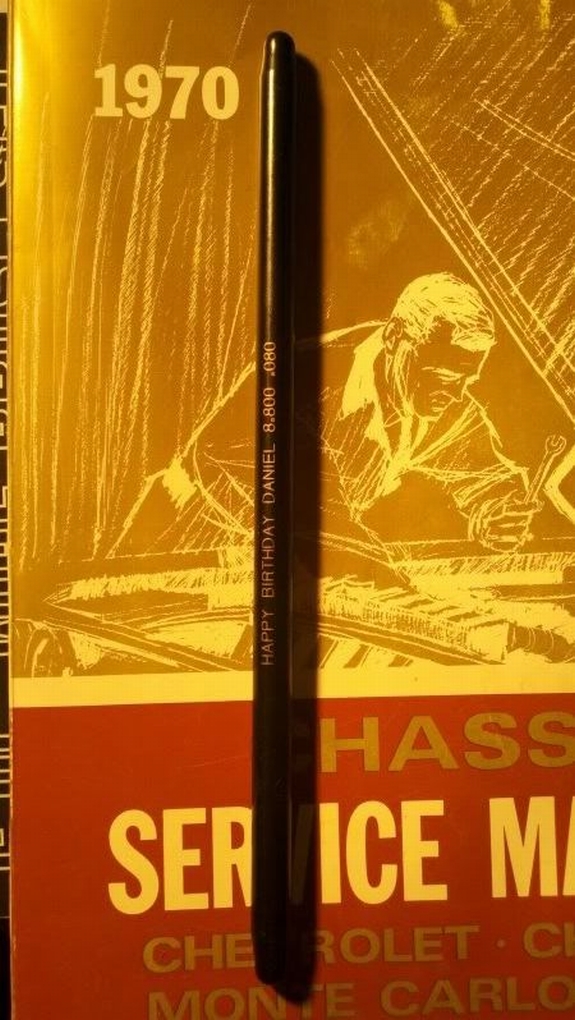

Trend’s laser etching, which occurs at lightning-fast speeds, is dictated by the customer and usually specifies relevant details.

But sometimes Mom’s have their say in the laser-etching process!

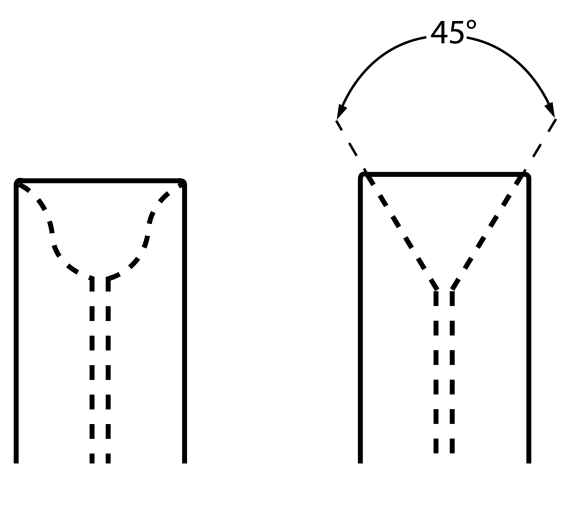

This checking fixture examines pushrod straightness in 3 places; it also monitors its overall length.

This automatic straightening machine, which is chiefly used on 5/16in and 3/8in., rotates each pushrod, monitors the rod for straightness, and corrects if necessary.

Manual straightening is performed on larger diameter pushrods—7/16in and greater